Technical Specifications for a High Capacity Wastewater Treatment Plant

Designing a large-scale purification facility requires a deep understanding of hydraulic engineering and material science. The equipment must be built to withstand continuous operation under harsh conditions while delivering precise separation results. Technical specifications dictate everything from the structural integrity of the tanks to the accuracy of the control systems. These details determine the reliability and longevity of the entire infrastructure.

A high-capacity wastewater treatment plant relies on robust engineering to handle massive volumes of fluid. Engineers must calculate surface loading rates, retention times, and sludge generation factors with great accuracy. The selection of materials and components is critical to preventing corrosion and mechanical failure. Only through rigorous technical planning can a facility achieve the high performance required by modern municipalities and industries.

Structural Design of the Wastewater Treatment Plant Tanks

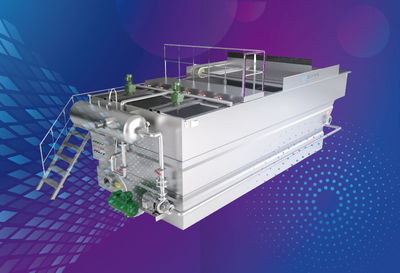

The tanks form the backbone of the treatment process, holding thousands of gallons of fluid. In a durable wastewater treatment plant, these structures are designed to optimize flow dynamics and prevent short-circuiting. The geometry of the tank influences settling efficiency and the effectiveness of chemical mixing. Robust construction ensures that the tanks can support the weight of the water and the mechanical equipment mounted on them.

Material Selection for the Wastewater Treatment Plant

Corrosion is a constant threat in wastewater environments due to chemicals and biological activity. The wastewater treatment plant utilizes high-grade materials like stainless steel or coated carbon steel for critical components. For aggressive chemical applications, specialized polymers or linings may be employed. Selecting the right material extends the service life of the equipment and reduces the need for expensive repairs and downtime.

Flow Distribution in the Wastewater Treatment Plant

Achieving laminar flow is essential for efficient particle separation. The wastewater treatment plant incorporates advanced inlet distribution systems to calm the incoming water. Baffles and weirs are strategically placed to ensure uniform velocity across the settling zone. This careful management of fluid dynamics maximizes the effective retention time, allowing for superior clarification results even at high flow rates.

Automation Systems for the Wastewater Treatment Plant

Modern facilities operate with a high degree of automation to ensure consistency and safety. The control architecture of a wastewater treatment plant integrates sensors, pumps, and valves into a centralized system. This allows operators to monitor the entire process from a single interface. Automation enables the system to react instantly to changes in influent quality, adjusting parameters to maintain optimal performance.

Chemical Dosing Control in the Wastewater Treatment Plant

Precise chemical addition is vital for coagulation and flocculation processes. The wastewater treatment plant uses automated dosing pumps controlled by real-time data from water quality sensors. This ensures that the exact amount of coagulant is added to match the current contaminant load. Automated dosing prevents chemical waste and ensures that the treatment process remains stable during load fluctuations.

Monitoring Sensors in the Wastewater Treatment Plant

To maintain control, operators need accurate real-time data. A smart wastewater treatment plant is equipped with a network of sensors measuring pH, turbidity, flow, and level. These instruments provide the feedback loop necessary for automated control strategies. Continuous monitoring allows for the early detection of potential issues, enabling proactive maintenance and preventing system upsets before they occur.

Performance Metrics of the Wastewater Treatment Plant

Engineers track specific data points to evaluate the success of the facility's design and operation.

- Flow Capacity: Cubic meters treated per hour.

- TSS Removal: Percentage of solids captured.

- COD Reduction: Efficiency of organic matter removal.

- Sludge Dryness: Moisture content after dewatering.

- Energy Use: Kilowatts consumed per cubic meter.

Conclusion on Engineering a Robust Wastewater Treatment Plant

The technical details of a facility define its ability to serve its community or industry effectively. A well-engineered wastewater treatment plant combines structural durability with smart operational controls. By adhering to strict specifications, engineers create systems that are safe, reliable, and efficient. This focus on technical excellence is what separates a high-performing facility from a problematic one.

As technology advances, the capabilities of these plants will continue to improve. The next generation wastewater treatment plant will be even more energy-efficient and automated. By leveraging data and advanced materials, the water industry is building the infrastructure needed for a sustainable future. This commitment to engineering quality ensures clean water for generations to come.